Commonly used configuration types of rolling mill bearings and their corresponding application characteristics

Aug 18, 2022

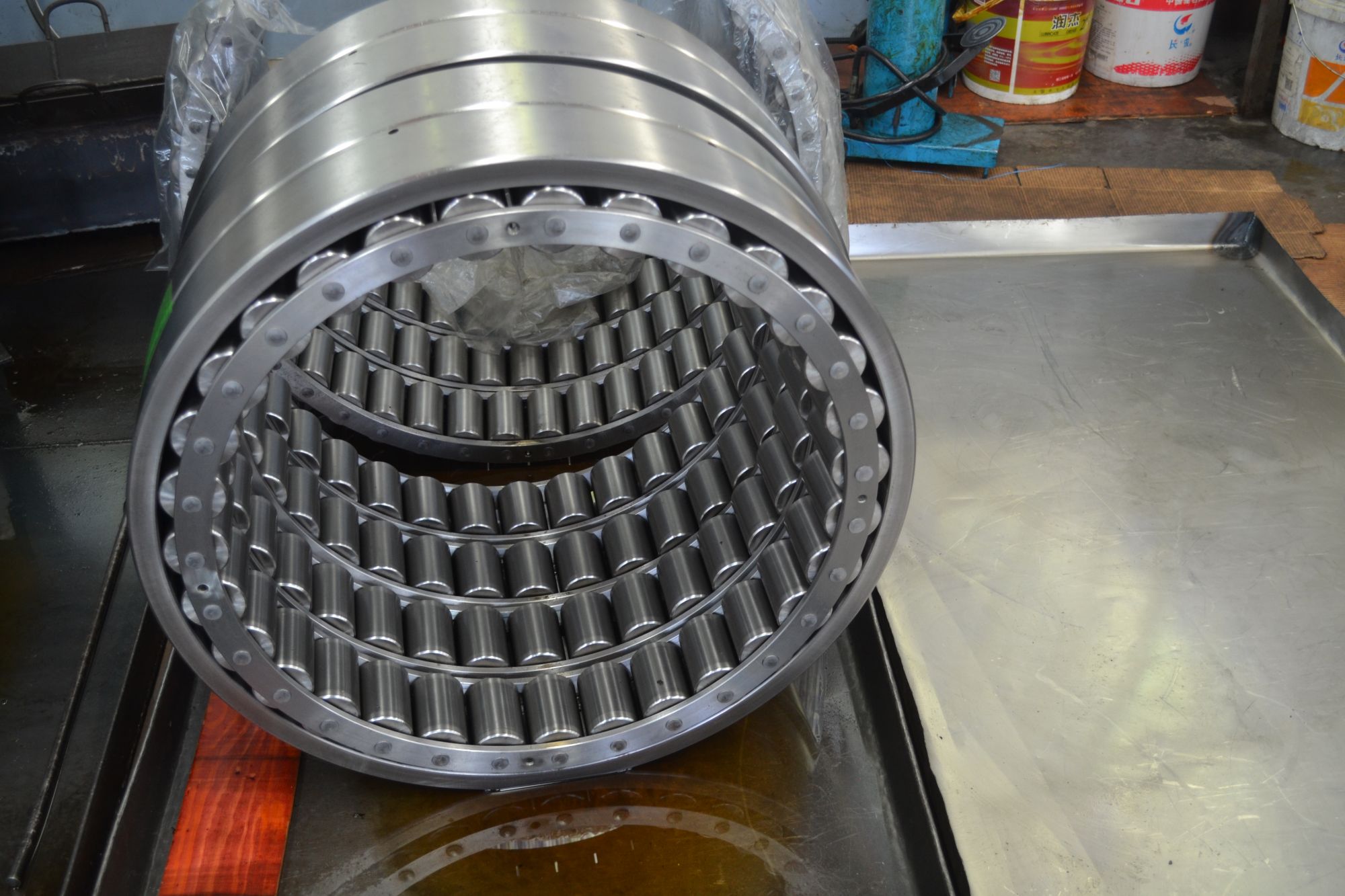

The most typical bearing in rolling mill bearings is the roll bearing. Roll bearings are important components used to support rolls and maintain their correct position in the frame. The size of the bearing friction coefficient is related to the rolling energy consumption; The service life of the bearing is related to the utilization rate of the rolling mill; The stiffness of the bearing has an impact on the dimensional accuracy of the rolled product. Therefore, rolled steel production requires roll bearings to have a small coefficient of friction, sufficient strength and a certain stiffness. On modern rolling mills, the structural form of roll bearings also needs to facilitate quick roll change operations. Typical types of roll bearings are four-row cylindrical roller bearings and four-row tapered roller bearings.

The common configuration types of roll bearings are as follows:

1. Four row cylindrical roller bearings + thrust bearings. Cylindrical roller bearings are mainly subject to radial forces, and thrust bearings are mainly subject to axial forces. When radial bearings and axial bearings are subjected to radial and axial forces respectively, the bearings are most likely to exert their speed performance. Moreover, axial bearings maintain a high axial guidance accuracy. This configuration type is currently the most widely used, mostly used in wire rod rolling mills, sheet mills, foil rolling mills, four-roll cold rolling mills and hot rolling mills and other support rolls.

2. Four-row tapered roller bearings. Tapered roller bearings can accommodate both radial and axial forces, so there is no need to have additional thrust bearings. This configuration type is more widely used, such as the four-roll hot rolling mill and the cold rolling mill's working roll, the embryo opener, the steel beam rolling mill and other rolls.

3. Spherical roller bearings. Spherical roller bearings can withstand both radial and axial forces, and the homogenization performance is good. This configuration was more popular in the early days, with a maximum rolling speed of up to 600 r/min. At present, in addition to the use in pipe mills, other rolling mills are generally less used.

What are the application characteristics of four-row cylindrical roller bearings for rolls?

The four-row cylindrical roller bearing used for roller includes two forms of inner diameter cylindrical hole and conical hole. Its main advantages are large load capacity, high limit speed, high manufacturing accuracy, tight fit between the inner diameter and the roll neck, simultaneous grinding of the roll body and inner race to improve the rotation accuracy of the roll system (the inner race can generally provide grinding amount for grinding), radial clearance can be controlled by grinding the inner raceway of the bearing, the inner and outer rings can be separated and interchangeable, and the production cost is low. Among them, the cylindrical hole is suitable for extremely high speed, and the conical hole is suitable for general speed. The main disadvantage is that it cannot withstand axial forces, so it needs to be equipped with a push bearing, and the bearing mounting space is large.

What are the application characteristics of four-row tapered roller bearings for rolls?

The four-row tapered roller bearing used for roller has two forms: cylindrical hole and tapered hole. Its main advantages are large load capacity, can withstand both radial and axial loads, small bearing installation space required, easy installation and dismounting; Its main disadvantage is that the cylindrical bore bearing is loosely mated with the journal, and there will be crawling phenomenon when running at higher speeds, resulting in bearing burn-in wear. Tapered bore bearings are closely matched with the journal, bearing and roller neck processing are difficult, loading and unloading require hydraulics.

What are the application characteristics of spherical roller bearings for rolls?

The main advantages of spherical roller bearings for rolls are that they have greater homogenization, easy to adjust the deflection of rolls and housings, large load capacity, can withstand radial and axial loads, and are especially suitable for impact loads; Easy loading and unloading. Its main disadvantages are lower limiting speed, lower axial guidance accuracy and shorter service life.

Because it is loosely mated to the journal, bearing crawling, burning and abrasion often occurs at higher speeds.

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.