Knowledge points and introduction about CHG's thin section bearings

Aug 30, 2022

Thin section bearings can achieve multiple functions according to different designs

Thin section bearings are highly accurate, very quiet and have a high load-carrying capacity. These ball bearings are available in three designs and are extremely small with mostly equidistant cross-sections. In these series, the cross section remains the same even for larger shaft diameters and bearing bores. These bearings are therefore called constant cross-section (CS). It is this characteristic that distinguishes thin section bearings in the standard ISO series from conventional bearings.

Therefore, it is possible to choose a larger cross section and use a bearing with a higher load capacity without having to change the shaft diameter. Thin section bearings can be designed to be extremely light and require very little space.

The relationship between thin section bearings and deep groove ball bearings, four-point contact bearings, and angular contact ball bearings

Thin section bearings are divided into metric and inch series. There are three different designs: deep groove ball bearing (C type), four-point contact bearing (X type), angular contact ball bearing (A type). All of the above designs are available in different series. Each series then depends on the size of the cross section, and the balls are matched to the series. CHG can provide products with different internal clearances, contact angles, lubrication methods, cage structures and other properties to meet the needs of most customers.

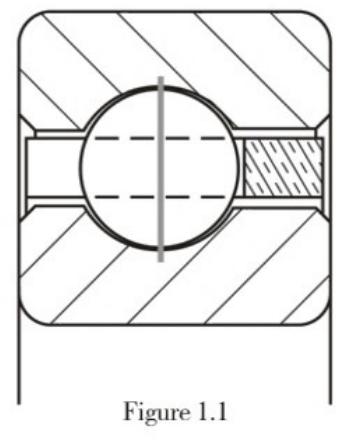

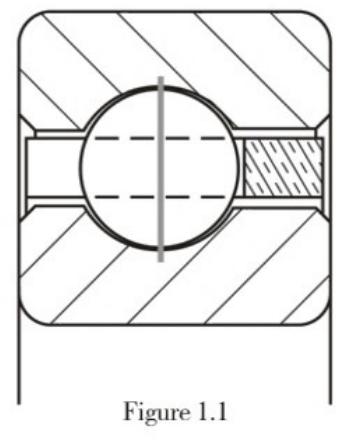

Deep groove ball bearings (C type) has an inner ring and an outer ring with super deep grooves (raceway groove depth =25% of the ball diameter). Usually, during the assembling process, place eccentrically the inner ring into the outer ring, and place a half of the quantity of balls to fill fully the groove, place concentrically the inner and outer ring, and uniform distribute the balls, and then assemble the cage. Deep groove ball bearings (C type) can support axial and radial loads in both directions.

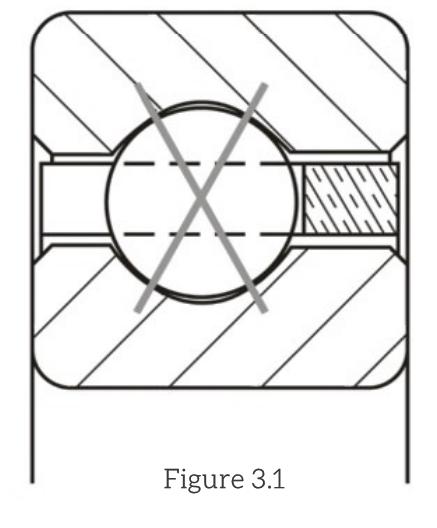

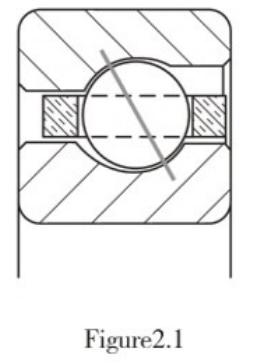

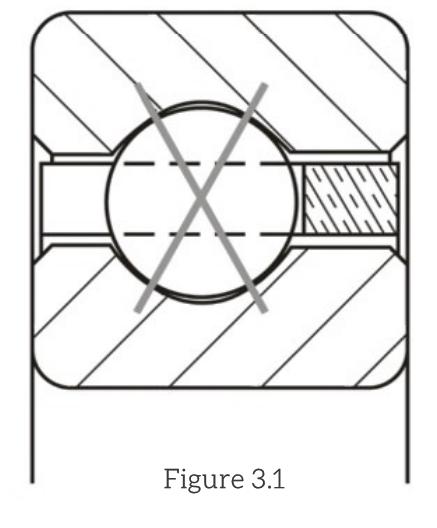

The groove depth of X type bearings is same as ones of A type and C type (25% of the ball diameter). The structures of the deep groove and the four-point contact allows the bearing to carry radial load, axial load and moment load, like a back to back configuration of paired bearings.

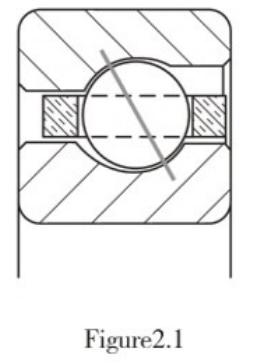

Angular contact ball bearings (A type) can match the optimum number of balls and have a contact angle of 30°. They support higher radial loads than deep groove ball bearings or four-point contact bearings, and can support axial loads originating from the same direction. For special requirements, angular contact ball bearings are also available as matching bearings. Therefore, the rigidity and load-carrying capacity of these combinations are much higher than single bearing products.

Compared with A type and C type bearings, the feature of Four-point contact ball bearings (X type) is its groove shape. For C type bearings, its center of raceway radius is in the center line of balls. For A type bearings, its raceway and ball is in an angular contact, the center of raceway radius is deviated from the centerline of balls and symmetrically distributed around the center line. For X ype bearings, there are 2 centers of raceway radius on each side of the raceway, both of which are deviated from the center line of balls. This structure forms a four point contact between the balls and the raceway of X-type bearings.

The groove depth of X type bearings is same as ones of A type and C type (25% of the ball diameter). The structures of the deep groove and the four-point contact allows the bearing to carry radial load, axial load and moment load, like a back to back configuration of paired bearings.

Characteristics and application fields of stainless steel thin section ball bearings

CHG stainless steel thin section ball bearings are made of 9Cr18 material, which is rust-proof and corrosion-resistant. Stainless steel thin-walled ball bearings have the same rolling elements and rings as other series of bearings, but the materials are all made of stainless steel and are equipped with corresponding seals and retainers. According to different structures, they can also withstand radial, axial and overturning forces. Stainless steel thin-walled ball bearings have the advantages of flexible rotation, stable operation, far less friction torque than sliding bearings, and long service life. But the overall bearing capacity is slightly smaller than that of ordinary bearings.

Share:

related news

-

Thin section bearings supplierJun 11, 2020Introduction to Thin-section Bearings Thin-section bearings are also known as slim bearings. The cross-section dimension is independent of bore diameter; therefore, thin-section bearings are also called uniform-section thin bearings.

-

How to choose the thin section bearing that is right for youJul 11, 2022Thin section bearings are widely used in many industries, and suitable thin section bearings can enable the main engine obtain good working performance and prolong its service life; it can also enable enterprises to shorten maintenance time, reduce maintenance costs, and improve the operation rate of machines.

-

Precautions for installation of thin section bearingsJul 18, 2022With the continuous development of modern industry in the direction of high-tech technology, the demand for precision bearings has also emerged. Thin section bearings realize extremely thin bearing sections, and also realize miniaturization and lightweight of products. However, the more precise the bearing, the higher the installation requirements. If it is used or installed improperly, it is easy to damage the service life of the bearing. Then, for the installation of thin section bearings, what problems should we pay attention to?