Application of Precision Thin Bearings in Encoders | CHG Bearing

Sep 14, 2022

When most people think about encoders, it feels like something very complicated and obscure and difficult to understand. In fact, it exists everywhere. You might find it in almost every machinery in every industry, it operates for motion feedback and motion control.

In an elevator, encoders tell the controller when the car has reached the correct floor, in the correct position.

In a printing application, feedback from the encoder activates a print head to create a mark at a specific location.

With a large crane, encoders mounted to a motor shaft provide positioning feedback so the crane knows when to pick up or release its load.

In a cut-to-length application, an encoder with a measuring wheel tells the control device how much material has been fed, so the control device knows when to cut.

On automated assembly lines, encoders give motion feedback to robots. On an automotive assembly line, this might mean ensuring the robotic welding arms have the correct information to weld in the correct locations.

No matter under which kind of application, the process is always same that the encoder generates a count then sends to the controller, the machine will perform a function accordingly.

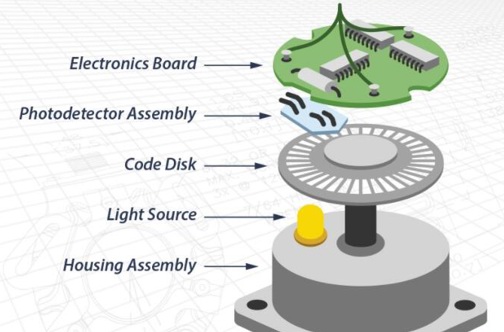

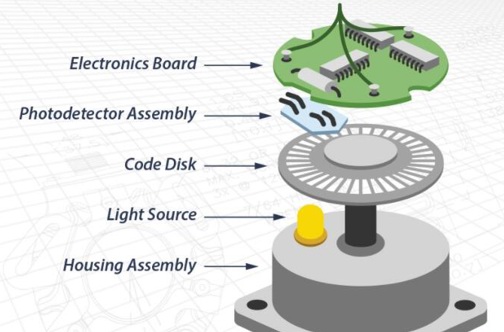

The different signal resources include: mechanical, magnetic, resistive and optical, while the optical being the most common. In optical sensing, the encoder provides feedback based on the interruption of light.

For some encoders in some industries, it needs precision thin bearings, or you may call it ultra-slim bearings, to reach the precision requirements.

CHG factory has been one of the leading military classified units and providing high-end P4 precision level ultra-slim thin bearings with equal crossed sections to satellites projects, blood medical equipment, radar systems, and many other machinery industries.

With Aichelin heat treatment technology and production lines adopted, CHG has won more and more customers globally. Except of being OEM for some top brands in the world, it also registered its own brand or logo: CHG, and it supports customization with very small MOQ since its complete technology research and development system based on factory, and also its in-time service 24 hours every day.

CHG factory welcomes every distributor, trader, end users to come for cooperation.

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.