FCDP type four-row cylindrical roller bearing application and installation instructions

Sep 27, 2022

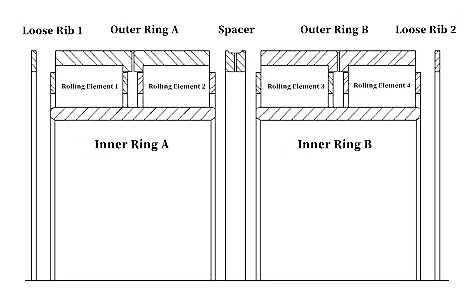

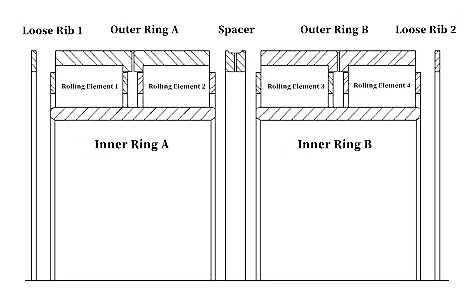

FCDP type cylindrical roller bearings, as typical rolling mill roll bearings, provide maximum radial load carrying capacity with low coefficient of friction compared to other types of bearings in a given mounting space. The bearings consist of two movable loose rib, a movable spacer, two outer rings, four row roller elements, and two inner rings.

Performance characteristics

FCDP type four-row cylindrical roller bearings, compared with the same size series of rolling bearings have five major characteristics.

High precision: high degree of structural separation, loose rib and spacer ring are movable separable ring, outer ring is close to the regular circular parts, inner ring is standard circular workpiece, its overall parts are regular geometry, more convenient for precision control of workpiece when machining.

Strong bearing capacity: rolling body design for hollow structure, cage pillar through the center of the rolling body to save the whole set of bearing rolling body circumferential arrangement space, compared with the same size series bearings so that the bearing can accommodate more rolling body, significantly enhance the bearing capacity.

Partial interchangeability: bearing outer ring assembly and inner ring can be separated, after installation the outer assembly is installed in the bearing box, the inner ring is installed in the roll journal by interference, the use process can realize the interchangeability between the inner ring and outer ring assembly.

Easy to check: after disassembly, the inner ring is installed in the roll journal following the roll journal as one, and the outer ring assembly is integrated with the bearing box, which can visually detect the bearing inner ring, rolling body, outer ring load area and other key parts of the use condition.

Easy to clean: bearing separation degree is high, inner ring, outer ring, spacer, roller elements, all of them can be separated, in the machine washing or manual cleaning can be efficient and fast cleaning adsorbed in the parts surface grease and foreign matter

Installation and use

Four-row cylindrical roller bearings should first complete the work of measurement, cleaning and inspection before installation. After the pre-installation preparation work is ensured to be completed, the bearings are disassembled and sealed. When disassembling the bearings, clean and neat gloves should be put on for operation.

Inner ring installation: the inner ring of the bearing is heated (recommended to use the ring electric induction heater for disassembly and installation), the heating temperature must be controlled between 80-100 degrees, not more than 120 degrees, to avoid the material tempering, reducing the hardness of the bearing itself, affecting the service life of the bearing, install the inner ring on the roll neck as soon as the temperature is reached, and squeeze the inner ring end face to apply pressure to ensure that the inner ring A end face and the labyrinth ring end face is in the fit state, the inner ring B and the inner ring A end face is in the fit state, wait for the inner ring to cool slightly and then relieve the pressure (to prevent the inner ring installation is not in place, the end face and the shaft shoulder is not fit).Strictly follow the regrinding dimensions and roughness provided on the regrinding drawing to ensure that the final dimensions after loading the roll diameter are within the dimensional tolerances and roughness requirements provided in the regrinding drawing.

Outer ring cage and roller elements installation:

1.Put in the retaining ring 1, then the overall combination of the installation of roller elements 1 and outer ring A, the installation process slowly put down, when encountered jamming with a copper rod hit the outer ring end face, to ensure that the outer ring A end face and retaining ring 1 tight;

2.Put in the roller elements, the installation process slowly put down, to avoid deflection, to prevent scratches on outer ring raceway and rolling body outer diameter.

3.Put in the middle spacer, and then install the whole assembly Put in the roller elements 3 and outer ring B, put them down gently during the installation process, and use a brass rod to hit the end surface of the outer ring when it encounters jamming to ensure that the end surface of outer ring B is tight with the spacer;

4.Put in the roller elements 4, put them down gently during the installation process to avoid deflection and to prevent scratches the outer ring raceway and the outer diameter of the rolling body;

5.Put in the retaining ring 2, and cover the bearing box gland

Gland assembly: After the outer component is installed, close the gland, measure the gap size between the end face of the bearing box and the end face of the gland with a stopper, and pad in the adjustment shim to ensure that the gap between the bearing gland extension and the stopper 2 is within 0.05mm or in a light preload state.

Note: Before stack mounting, apply grease to the inner ring surface of the roller neck to prevent the assembly from scratches, and rotate each of the four columns of the rolling body one turn after completing the installation to ensure flexible rotation.

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.