Assembly and disassembly of tapered roller bearings

Tapered roller bearings can be mounted directly on a tapered shaft or on a cylindrical shaft through an adapter sleeve or withdrawal sleeve. A tight fit is obtained by axially moving the inner ring. The tight fit of the inner ring can be effectively controlled by measuring the reduction in radial clearance caused by the expansion of the inner ring.

When installing medium-sized bearings, a large amount of force must be applied to tighten the nuts. A lock nut with a thrust bolt can make the entire process easier.

When installing large bearings or pressing bearings onto sleeves, hydraulic methods are more appropriate. Hydraulic nuts are suitable for standard bushing and shaft threads.

2. Disassembly of tapered roller bearings

To disassemble a bearing mounted directly on a tapered shaft or an adapter sleeve, first loosen the locking device on the shaft or the lock nut on the adapter sleeve, loosen the nut by the same distance as when tightening, and then Then use a hand hammer and casing to remove the inner ring from the adapter sleeve or shaft. When disassembling with a press, press the bearing against the adapter sleeve.

Bearings fixed with withdrawal sleeves are disassembled with compression nuts. However, disassembly of large bearings requires a lot of force. At this time, the thrust bolt can be used in conjunction with the compression nut, and a washer can be added between the inner ring of the bearing and the bolt.

Using hydraulic nuts and withdrawal sleeves to disassemble bearings is a simple and economical process. Using hydraulics when disassembling large bearings makes disassembly very easy. As long as oil is pressed between the mating surfaces, the mating parts will be easily separated without damage.

There must be oil grooves and oil holes on the conical shaft, and the oiler can generate sufficient pressure.

Large adapter sleeves or withdrawal sleeves must be pre-processed with oil grooves or oil holes. The oil pressure required during disassembly needs to be adjusted with an oil pump.

-

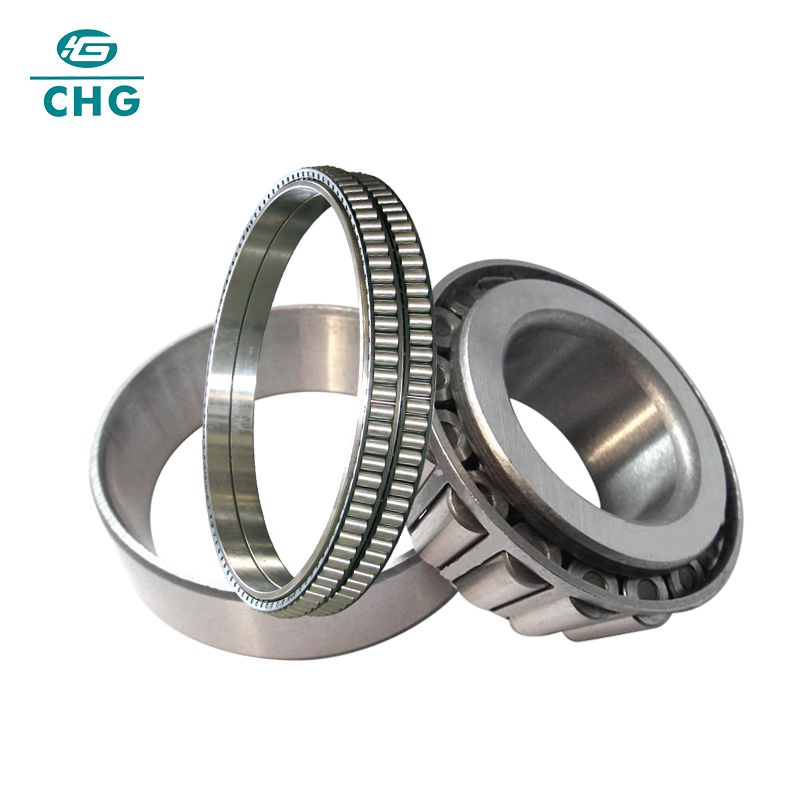

Four row tapered roller bearingsMar 14, 2024It usually consists of two double-row inner rings, a double-row outer ring and two single outer rings. There is an inner spacer ring between the two inner rings, and there are two middle spacer rings between the three outer rings. Such a design The bearing can adjust the clearance to adapt to different working conditions.

-

Application of rolling mill bearingsFeb 28, 2024Rolling mill bearings should be selected according to the type and working characteristics of the rolling mill. 1. Billet opening machine and billet mill: This type of rolling mill generally has a large rolling force and strong impact load, but the speed is not high;

-

CHG Bearing:High quality rollers-rolling elementJan 25, 2024CHG Bearing can produce all kinds of high-precision cylindrical and tapered rollers in the range of φ15mm to φ160mm in diameter and 20mm to 220mm in length, with an annual output of 10 million pieces and product precision up to G1 and G1A (Grade I) standards. More than 150 sets of various precision equipment, and various perfect special testing instruments, ultrasonic flaw detection (UT), magnetic particle flaw detection (MT), eddy current flaw detection (ET) instruments, spectrometer, carbon and sulfur analyzer, roundness meter, contour roughness meter, etc.

-

Types of thin-section bearingsDec 29, 2023Firstly, Thin-walled ball bearings with equal cross-sections. Secondly, Crossed roller bearings of equal cross-section have cylindrical rollers arranged crosswise on the V-shaped raceway, and the rollers are separated by isolation blocks.