CHG Bearing:Bearings for wind turbines

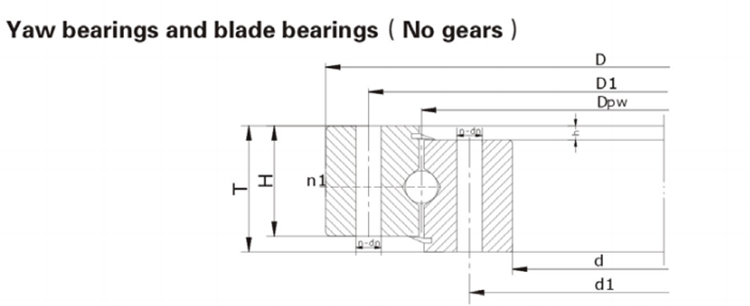

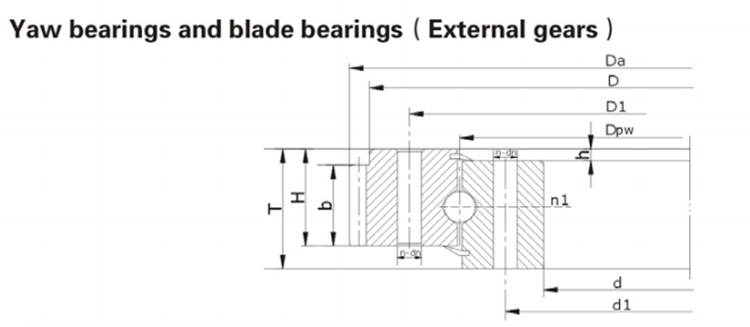

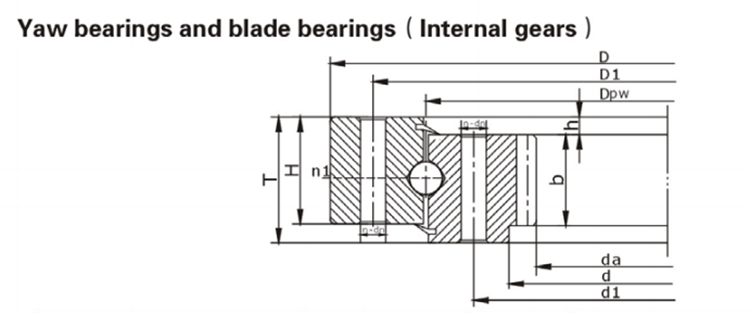

Blade bearings are used to connect blades with hubs in MW wind turbines, and they also can adjust the windward direction of blades to ensure electricity production with power rating and the safe work of wind turbines. Usually, single or double rows four-point contact ball slewing bearings are used as blade bearings, which have preload, special designed seals, anticorrosion surfaces,etc.

Yaw bearings can adjust the windward angle of the cabins and rotors to keep them facing into the wind as the wind direction changes, so wind turbines can produce the maximal amount of electrical energy at all times. Generally, four-point contact ball slewing bearings or crossed cylindrical roller slewing bearings are adopted, whose clearances are close to 0 or preload. In addition, they have special designed seals, and their surfaces are anticorrosion.

There are many kinds of wind turbines. However, the horizontal axis wind turbines are most widely used, and 75%- -80% of which have the structure of inner rings are installed on the rotary main shafts, namely main shaft bearing support structure. 240 or 241 series spherical roller bearings are almost suitable for the fixed and floating ends of main shafts in the structure according to the ratio of radial and axial forces. In other remaining HAWT, bearings' outer rings rotate with hubs, and inner rings are installed on the stationary main shafts, that means hub bearing support structure. This kind of main shaft bearing system commonly includes double-row tapered roller bearings that are preset axial clearance on fixed ends and cylindrical roller bearings on floating ends. Besides, three- -row cylindrical roller combination slewing bearings are also used as main shaft bearings to carry radial loads, axial loads and loads moment.

There are many varieties of gearbox bearings. The main types are NU, NCF and NJ types cylindrical roller bearings and tapered roller bearings. The bearings can be lubricated with gear oil in gearboxes. However, there are many metal particles in that oil, so the bearing life will be shortened. Therefore, good filtration system must be adopted, and bearings should have special heat treatment to form compressive stress on the raceways, reduce the sensitivity of raceways and prolong the life. Furthermore, the surfaces of rollers can be superhard to resist abrasion by coating.

Generator bearings utilize cylindrical roller bearings or deep groove ball bearings, which have the good performance of low noise by improving design structures and processing technics.

-

CHG Bearing:The lifespan of bearingsMar 28, 2024The bearing life refers to the number of revolutions or hours experienced by the bearing before the occurrence of pitting under a certain load. The life of rolling bearings is usually defined by the number of revolutions or the number of hours worked at a certain speed. During this lifespan, no initial fatigue damage (such as spalling or defects) should occur on any bearing ring or rolling element.

-

Assembly and disassembly of tapered roller bearingsMar 21, 2024Tapered roller bearings can be mounted directly on a tapered shaft or on a cylindrical shaft through an adapter sleeve or withdrawal sleeve. A tight fit is obtained by axially moving the inner ring. The tight fit of the inner ring can be effectively controlled by measuring the reduction in radial clearance caused by the expansion of the inner ring.

-

Four row tapered roller bearingsMar 14, 2024It usually consists of two double-row inner rings, a double-row outer ring and two single outer rings. There is an inner spacer ring between the two inner rings, and there are two middle spacer rings between the three outer rings. Such a design The bearing can adjust the clearance to adapt to different working conditions.

-

Application of rolling mill bearingsFeb 28, 2024Rolling mill bearings should be selected according to the type and working characteristics of the rolling mill. 1. Billet opening machine and billet mill: This type of rolling mill generally has a large rolling force and strong impact load, but the speed is not high;